If the bore or shaft size you are using is not listed, select the ORing with an inside diameter just smaller than the shaft you are using If you are designing a face seal, select the ORing with an inside diameter which will position the ORing on the side of the groove opposite the pressure Click here for more information on face seal groove design Note the ORing inside diameter forPiston seals Orings Large diameter radial shaft seals Wear sleeves SKF SPEEDISLEEVE Large diameter wear sleeves Rod seals Backup rings Cassette seals and sealing units Axial shaft seals Vring seals Metalcased Vring seals & axial clamp seals Mechanical seals Wiper seals Guides 4 Radial shaft seals Whenever a shaft rotates, it needs a bearing arrangement for smooth andRadial shaft seals with a low cross sectional height Cassette seals Wear sleeves Track pin seals Metal face seals Vring seals Axial clamp seals Sealing and spacing washers Hydraulic seals General technical information Piston Seals Rod and buffer seals Wiper seals Guide rings and guide strips Orings and backup rings Fluid

Shaft Seals For Rotating Shafts

O-ring shaft seal design

O-ring shaft seal design-• Housing design & tolerances • Cords, kits & lubricants Issue 7 2 To order or get further details, call your local contact shown on rear cover or listed at wwwjameswalkerbiz 'O' Ring Guide Introduction The 'O' ring, or toroidal seal, is an exceptionally versatile sealing device Applications, ranging from garden hose couplings to aerospace or oil and gas duties, make it theIn 06, Seal & Design moved into Canada with the purchase of Able ORings and Seals Today Seal & Design Canada is a recognized leading supplier in the Toronto and Southern Ontario markets In 11 and again in 14, we expanded our warehouse facility to a grand total of 91,000 square feet of manufacturing and office space In 15, Seal & Design acquired Higbee Gaskets

Radial Shaft Seals Dynamic Rotary Lip Seals Freudenberg Fst

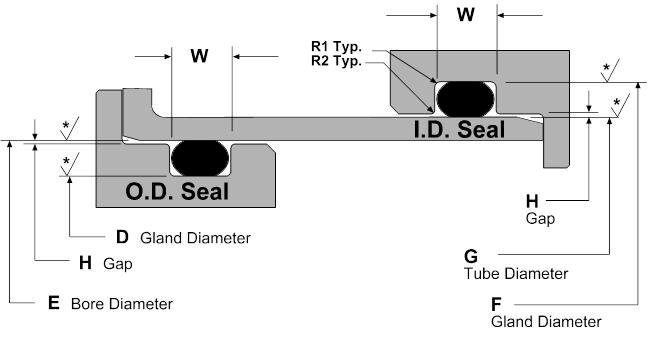

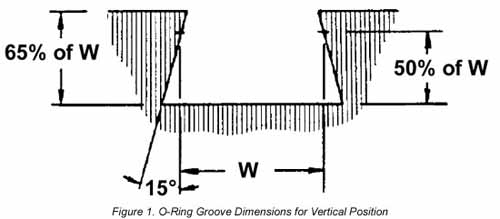

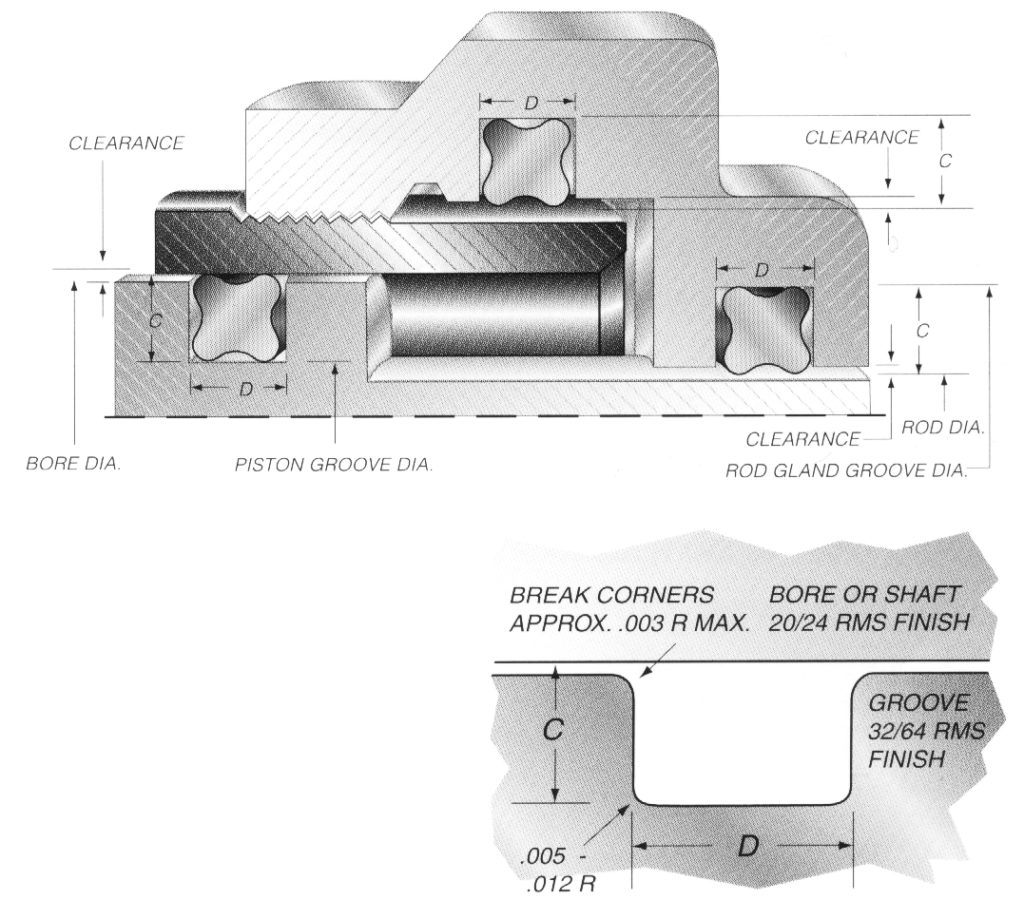

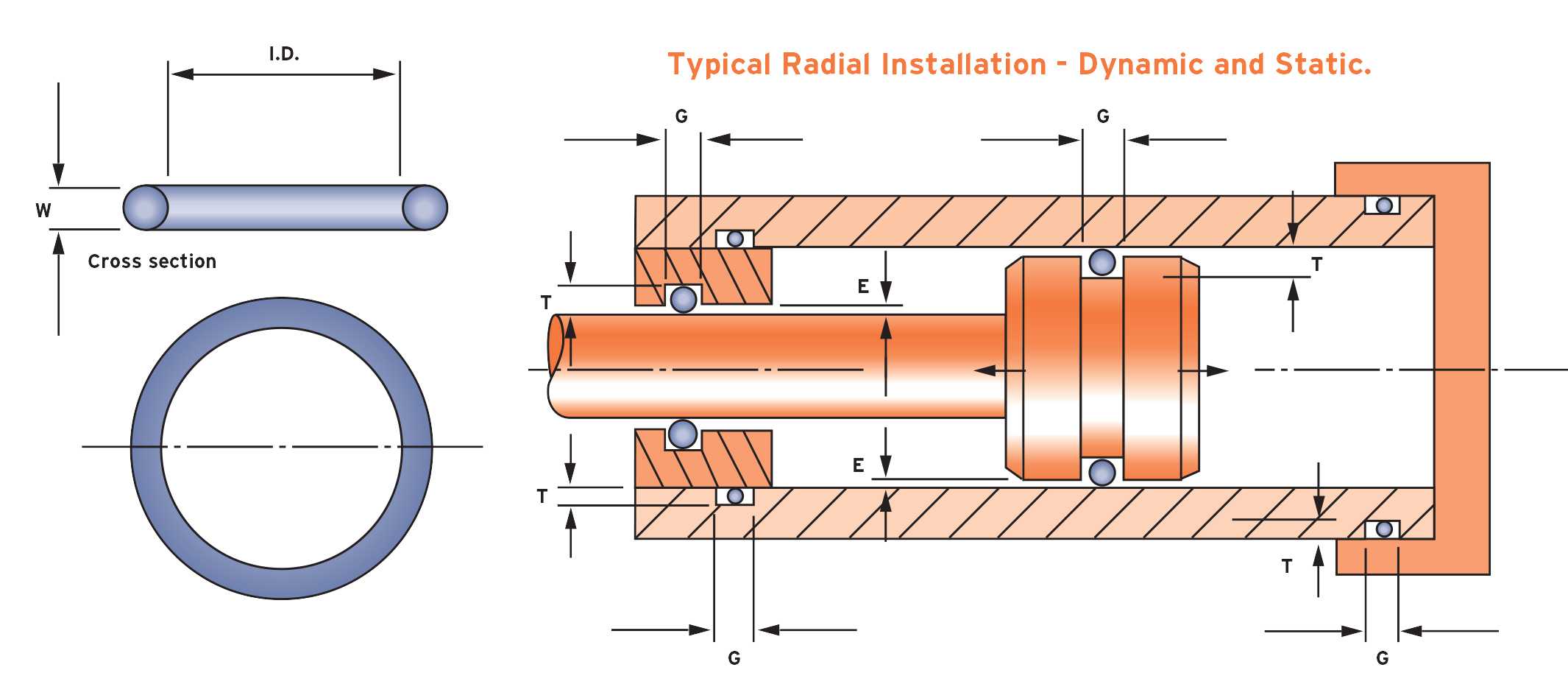

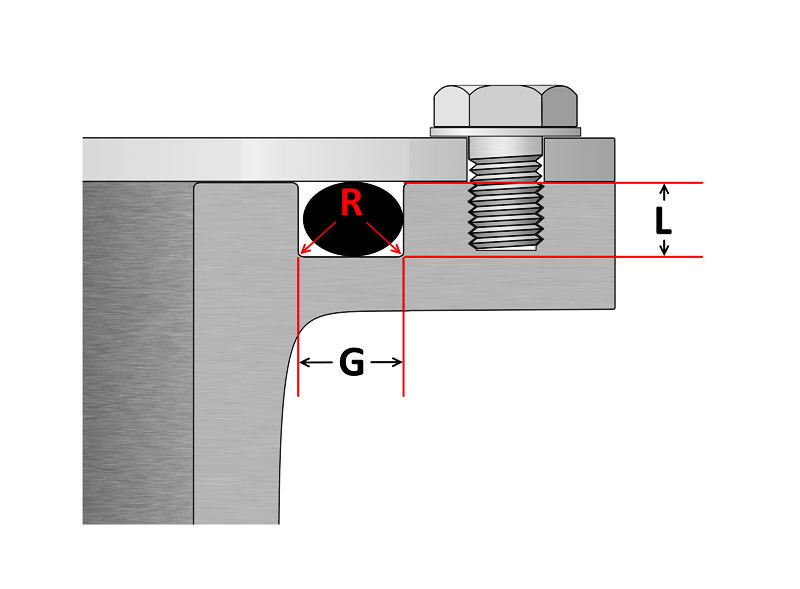

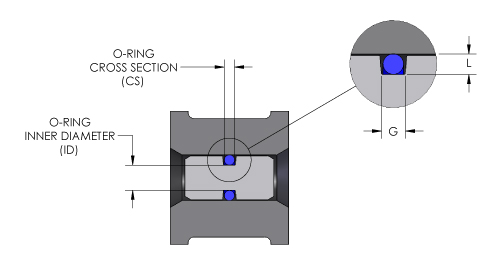

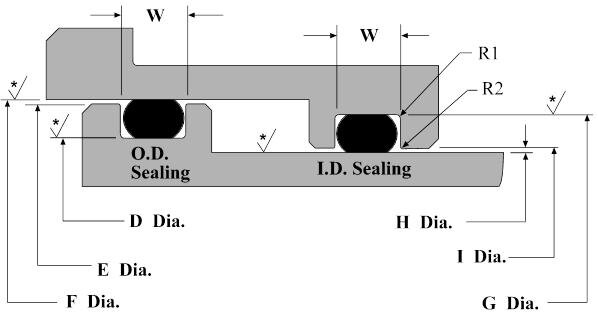

Groove Design ORing Seals for Static and NonRotary Dynamic Applications Speak to an Engineer About Your Project Crosssection Select an ORing crosssection size from the available standard sizes If you are unsure what crosssection size to use, see here Clearance Determine the maximum clearance present in your application For a radial seal, subtract the minimum rod (shaftIt is a elastomer with a round crosssection designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface10 ORING SEALS – THEORY AND DESIGN PRACTICES Theory An oring seal consists of an oring and a properly designed gland which applies a predictable deformation to the oring The gland is basically a groove dimensioned to a certain height "H" and width "W" (Figure 1) to allow a fixed compression of the oring when the gland flanges make metal to metal contact It is also

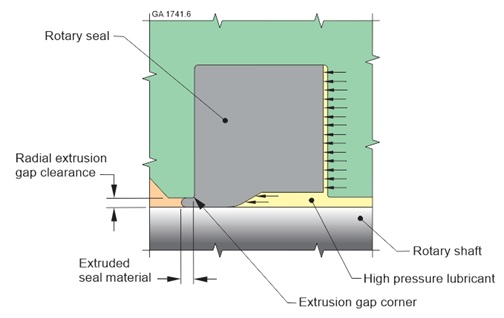

General Engineering Menu ORings Suppliers Molded ORings Services ORings Design Guidelines, Specifications, Materials An Oring , also known as a packing , is a flexible gasket in the shape of a loop; The biggest weakness of radial Oring seals is that the clearance between components creates a path for the Oring to extrude due to the pressure acting on it Components called backup rings can help alleviate this Backup rings are designed to spring out of the gland and block the extrusion gap Where an Oring alone could withstand perhaps only 00 psi, a backup ringAn Oring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus;

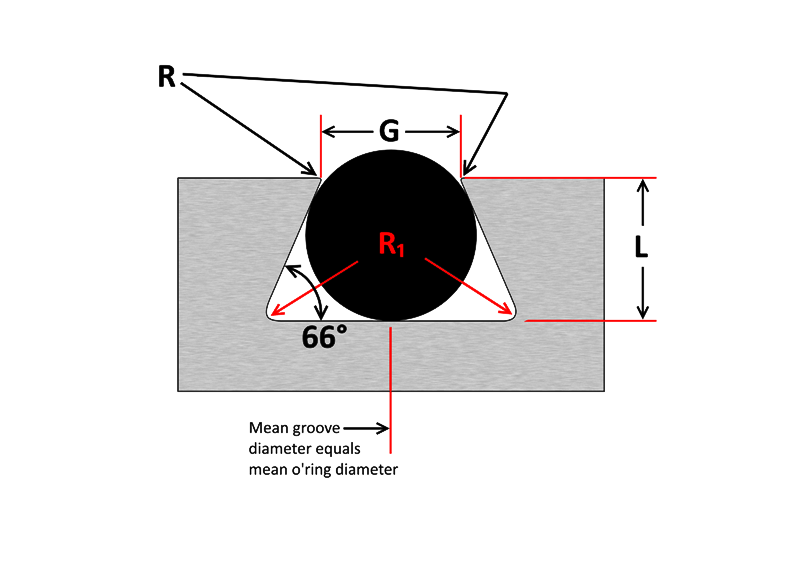

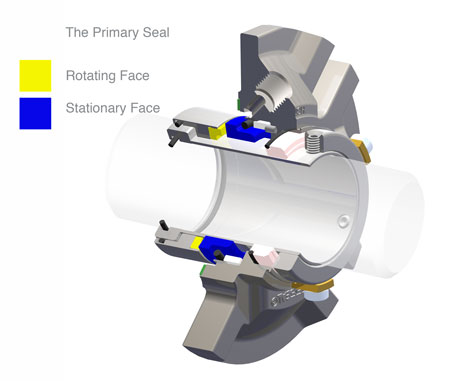

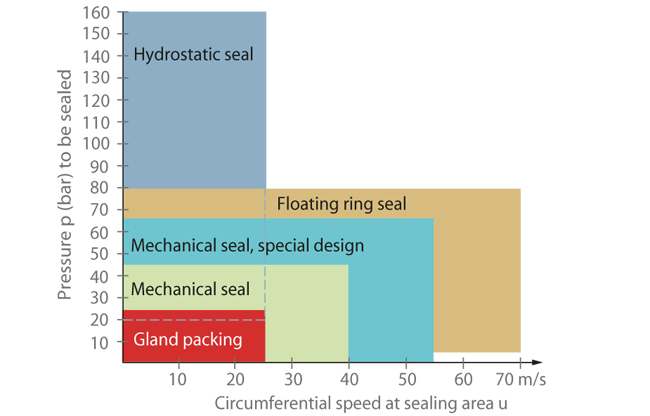

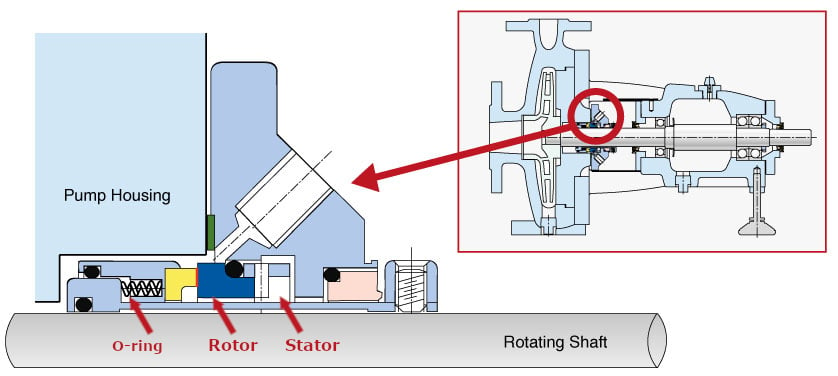

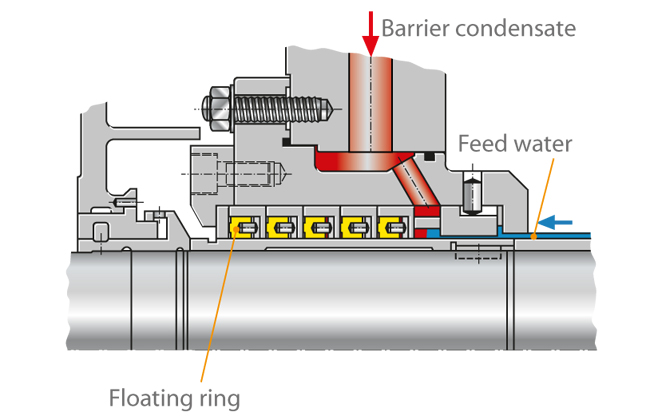

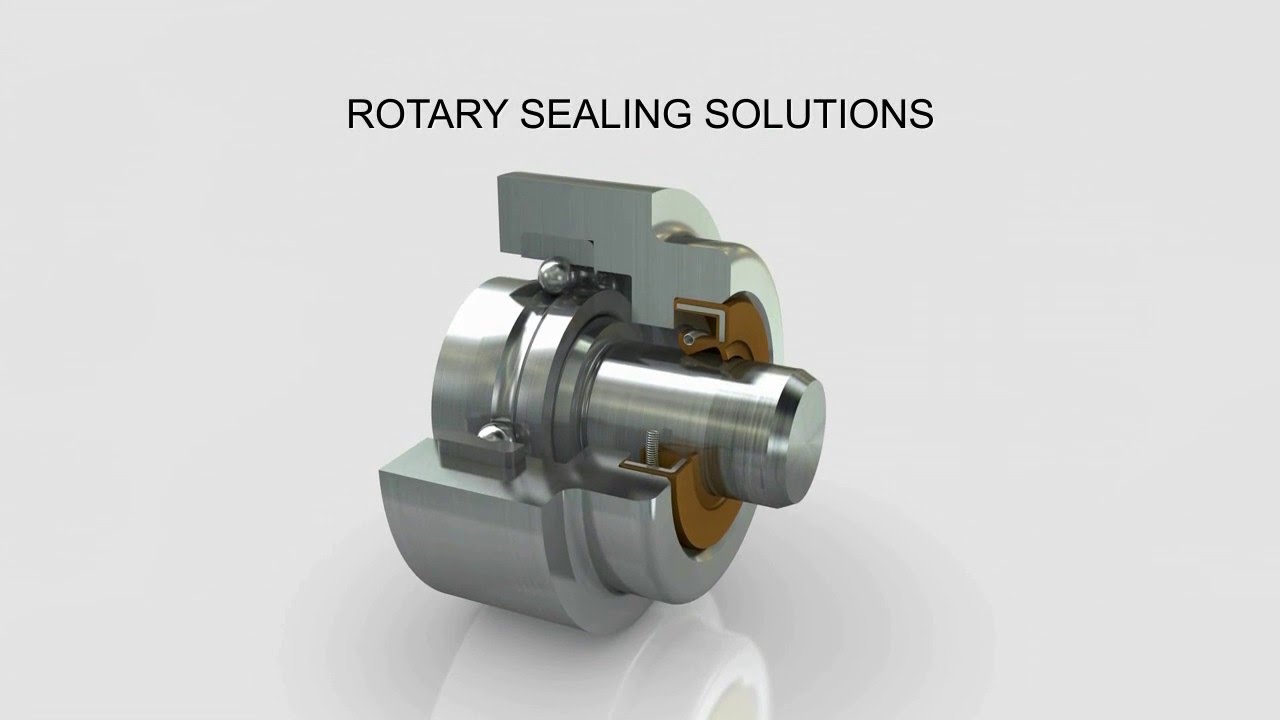

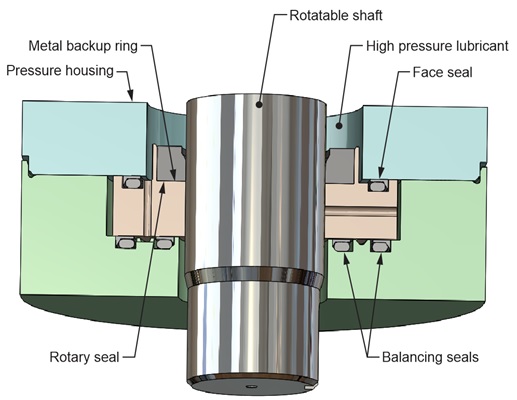

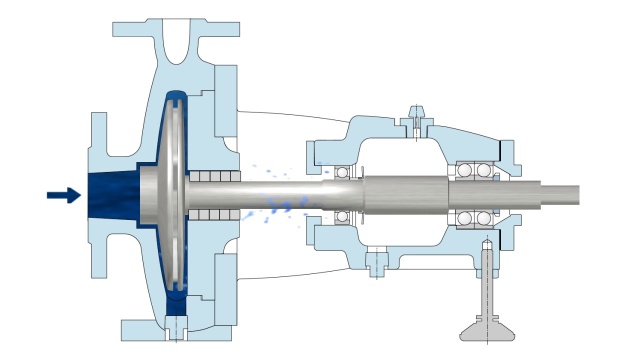

The oring seal design process begins with understanding the gland type in which the seal will be seated To ensure the oring fits properly it is recommended that the oring is stretched 1 to 5% circumferential, with ideal stretch at 2% Further considerations listed below include;The appropriate seal type for the individual pumping requirements is chosen from a wide variety of different shaft seals The design is based on one of the two following principles sealing by means of a narrow radial gap (parallel to the shaft axis) or a narrow axial gap (at a right angle to the shaft axis) For both sealing principles, the gaps may either employ a contact or noncontactMechanical shaft seal Oring, stationary Oring, rotating Spring Torque transmission element Introduction 3 Operating principle This section describes how the lubricating film is generated in the sealing gap in a liquidlubricated mechanical bellows shaft seal The design differs slightly from the Oring seal shown in fig 19 In its simplest form, the mechanical shaft seal consists of

Rotary Sealing With High Pressure Seals Kalsi Engineering

Your Guide To Choosing The Best Rotary Shaft Seal

Please follow the steps below to determine the appropriate double chamfer seal or Dring design (1) In Design Table 1, match the Oring 2 series (0, 300, or 400) with the existing groove and ensure the existing groove dimensions match the recommendations based on the number of backup rings used with the original Oring The Design Table 1 will also give the recommended crossOrings Among all the large variety of seal products that M Seals provide, the Orings is the most versatile and is found in nearly all kinds of machinery and equipment Not surprisingly, Orings are our largest product group, and we stock a wide range of standard dimension for example according to ISO3601, AS568A and SMS in all the commonThe squeeze or rate of compression is a major consideration in Oring seal design Elastomers may take up the stackup of tolerances of the unit and its memory maintains a sealed condition Orings with smaller cross sections are squeezed by a higher percentage to overcome the relatively higher groove dimension tolerances 3 Application Design Orings can be successfully used in static

Static O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

Shaft Seals For Rotating Shafts

The elastomer oring concept has been explored in two addi¬ tional ways These are the use of orings of small cross section in the tongue and groove flange design and the use of orings between flat plates Viton A^ ^ orings of 1/16 inch cross section diameter have made satisfactory seals in a tongue and groove flange design andRubber Seals, Sealing Devices & ORing Seal Design AppleAn instructional video on how to assemble an oring seal on a 40K cell piston rod

Oring Ehandbook

Hydrapak Seals Products O Rings Size Dimensions

ORing Handbook Parker Hannifin ORing Diision Europe ORing Handbook Parker Hannifin ORing Diision Europe Preamble Sealing technology by ParkerPrädifa The Engineered Materials Group of the Parker Hannifin Corporation is the worldwide leader in the field of designing, developing and manufacturing sealing systems, vibration dampers, EMI shielding systems and heatEND COVER NILOS SEAL PISTON SEAL OTHER SEAL ORING KITS PNEUMATIC SEAL BACKUP RING To equip your bearings , 123Bearing offers a wide range of oring seals, rotary shaft seals, vring seals, hydraulic seals and moreOur oring groove design guides list default oring groove dimensions for the most basic applications and are intended to be used with the following oring groove design considerations to engineer on oring gland to optimize specific application performance The wrong size groove makes even the best oring underperform Trust and Choose Marco Rubber & Plastics For more

Shaft Seal Ksb

V Ring Seals Seal Design Inc

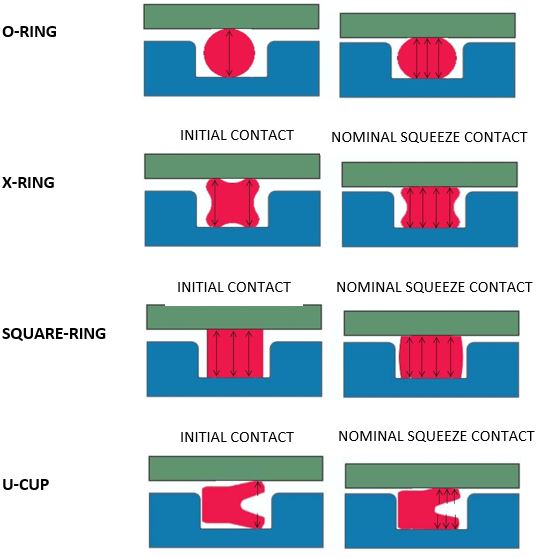

Gland Designs for QuadRings®/XRings Therefore Oring seals are not recommended for speeds less than 1 foot (0,3 m) per minute when the pressure difference is less than 400 psi (27,5 bar) A good solution to avoid spiral failure is the use of QuadRings®/XRings QuadRings®/XRings are used in many dynamic applications where Orings provide less than satisfactory performanceORINGS An ORing is a widely used sealing ring with a circular crosssection designed to fit in a groove ORings are a very popular choice of sealing due to their simple form, low cost, reliability and minimal space requirements in the application We carry extensive stock of ORings in NBR, HNBR, FKM (Viton®), FFKM, EPDM, SiliconeSeal gland type, sealing application (fluid, solid gas), pressures, operating temperatures, and chemical

Mechanical Seals Totally Seals

Metric Oil Seals Shaft Seals Oil Seals Houston

For a highpressure seal to work to optimal levels, oring design and manufacture again depends on choosing specific materials for better performance under specific conditions Orings function on the principle that even pressure placed on the (more or less incompressible) oring material creates predictable deformation patterns around the perimeter of the gasket in its groove ThisThis Oring seal design section will give you step by step instructions on how to design a seal or rubber part for your application Consider this a rubber guide or Oring guide in helping you find the exact rubber material and size you need Some parts of this online rubber or Oring design guide can be downloaded in PDF but everything can just be printed directly from our website for yourDesigning the parts of an application where orings will be applied is broadly termed "oring groove design" In order to seal properly, the oring has to deform in the application by being compressed and stretched in any number of ways The design of the groove where the oring sits plays a major role in how the oring performs its sealing role Extrusion Limits;

Rotary Shaft Seal Shaft Seals American High Performance Seals

Llis

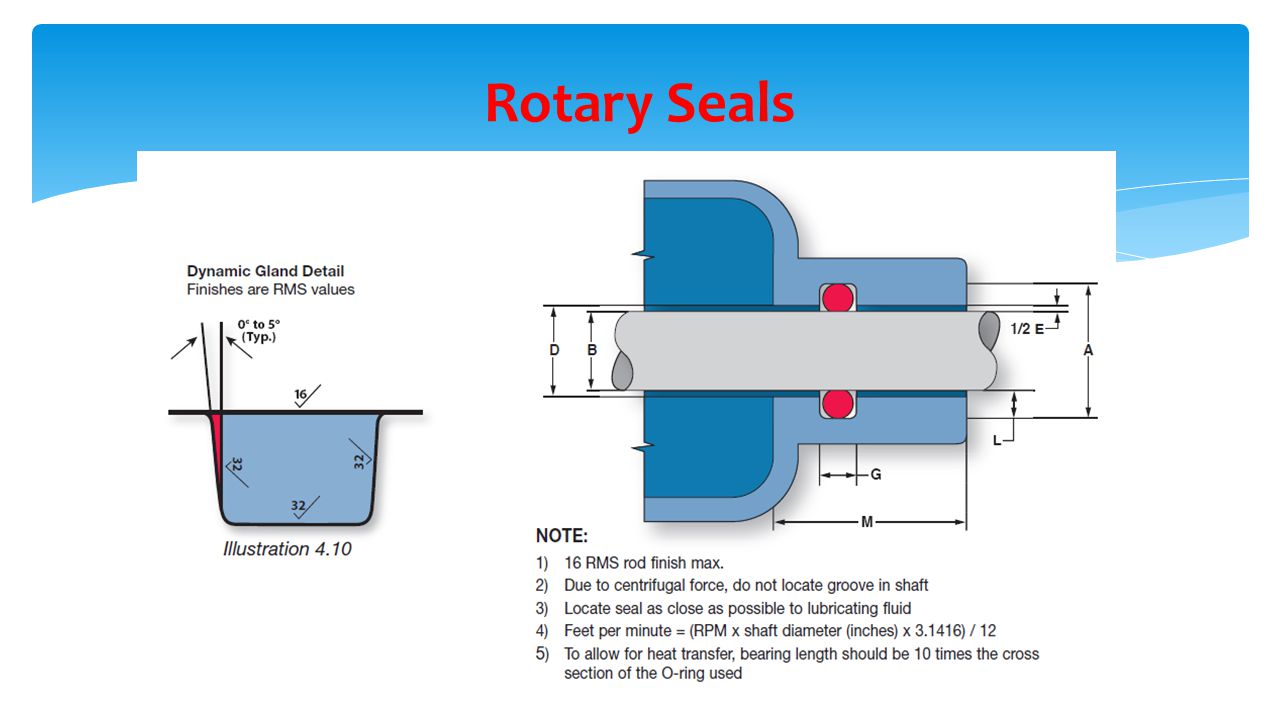

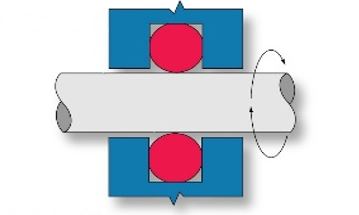

Dynamic Rotary ORing Gland Design In a dynamic rotary seal applications a turning shaft protrudes through the ID of an oring, the oring then becoming a seal The table below lists recommended dimensions for dynamic rotary seal glands by AS568A oring dash numbers Static Radial Glands Axial Internal PressureOring gland design information Please contact the local ERIKS representative if an application does not clearly fall into these design parameters Static Applications There are five types of static Oring applications • Flange seal • Radial seal • Dovetail seal • Boss seal • Crush seal Flange Seal (Axial Seal) In flange seal glands, the two flanges are assembled with metal toOrings and backup rings maintain sealing contact force by radial or axial deformation in the seal housing between two machine components The most important criteria that influence the maximum operating pressure at which Orings in static radial sealing can be used

O Ring Groove Design Sealing Australia

Seal Solutions Guide

It is a loop of elastomer with a round crosssection, designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface The Oring may be used in static applications or in dynamic applications where there is relative motionORing Seal Design Standard AS568 ISO 3601 Example ASN Nitrile Oring (AS Size 0070 CS x 0614 ID) Oring Standards Oring Search Tools Measured on ShoreA hardness index Shore A = Rubber Band Shore 40A = Pencil Eraser Shore 60A = Car Tire Tread Shore 70A* = Running Shoe Sole Shore 80A = Leather Belt Shore 100A = Shopping Cart Wheel ORing Hardness OOring groove design guides offer default dimensional guidance on the most basic oring groove design applications The best orings are useless without the right groove design which becomes increasingly important the more demanding the application environment Review the general oring groove design considerations before moving onto the specific oring gland design type

Oil Seals Radial Oil Seals Trelleborg

Oil Seals Seal Design Inc

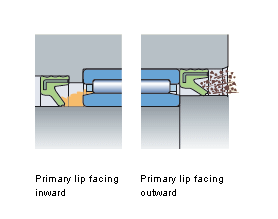

O ring seals whether you require a standard off the shelf seal, or a specialised design to solve your unique problem – we have the answer We keep a huge range of different types of seal, in a variety of materials and diameters for any applicationAn Oring seal is a means of preventi ng unwanted leakage or loss of fl uid or gas (i e media generally) The Oring is the most popular form of seal as it is simple to install and needs litt le installati on space Given correct grooving and material choice, the seal can be used for a very long ti me within the rubber's temperature limits both as a fi xed and as a moving part DescriptiThe seals for linear motion are shaft seals in which the primary sealing lip has a specific design, enabling it to support linear movement We also offer custommade shaft seals that are subject to certain constraints, such as those for shock absorbers or steering racks FRANCE JOINT O'Ring Hydraulic seal Rotary seal Oil seal Pneumatic seal Static seal Face seal EN FR;

Advantages Of A Quad Ring Over An O Ring

Www Pressureseal Com Orings Oguide Pdf

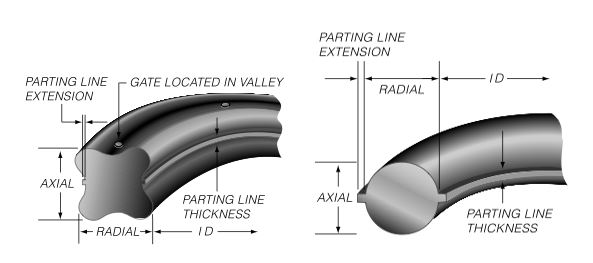

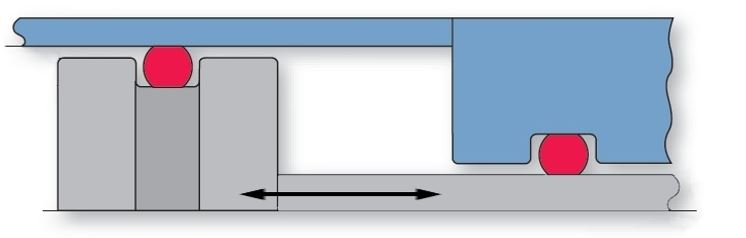

Created Date AMAn Oring has proved to be a practical rotary shaft seal in many applications With the correct design, Parker ORing rotary seal compound N, will provide satisfactory service at surface speeds up to 1500 feet per minute The design conditions are most critical for rotary seals, as would be expected Relatively high durometer compounds, close control of tolerances, andReciprocating seals are a dynamic version of either a male radial or female radial Oring design In a reciprocating seal, there is relative reciprocating motion (along the shaft axis) between the inner and outer elements This motion tends to slide or roll the Oring, or sealing surface of the Oring, back and forth with the reciprocal motion Examples of a reciprocating seal would be a

V Rings All Seals

O Ring Groove Design Guides Engineering Quick Reference

Orings are the epitome of elegant engineering The ring itself costs only a few cents, and the groove it goes in is simple and easy to manufacture But desp ORings can be made from plastic or metal, but for the purposes of our blog, we'll focus solely on rubber – or elastomeric ORing design An ORing, also known as a "torus," works in tandem with the glands in which they are installed The gland is normally cut from the metallic hardware, and works with the ORing to seal The glandTo find the groove dimensions on a rotating seal, use Design Chart 5 Find the shaft size in the second column The groove root diameter and width will be found under their respective columns The Pressure Seals Oring size will be found in the first column next to the shaft diameter BACKUP RINGS (Design Chart 7) When you have a tendency for Orings to extrude between the

Duramax Marine Shaft Sealing Systems Drymax Stern Tube Seals

Fundamentals Of Mechanical Seals Seal Faqs

O rings are one of the most common oil seals used in modern machinery These loops of elastomer rubber are designed to fit seamlessly into a groove and are then compressed to form a seal at the interface between the two parts Affordable, reliable, easy to manufacture and a snap to use, they can be used in hydraulic pistons and hydraulic shaft applications They are suitable for use in theFrom the finest precision seals to the largest heavy duty shaft seals and packings Our products address the needs of customers that wish to have a broad range of products and solutions at hand The company was founded in 1963 and now has offices in 6 countries M Seals entered the UK market in 14 and through its 3 distributionAnd (b) nonpusher type using some form of bellows of elastomer or metal 7 ( Table 54 ) Figure 56a

Www Fluorotec Com Media 2191 Aft Seals Design Handbook Pdf

Groove Design O Ring Seals Minnesota Rubber Plastics

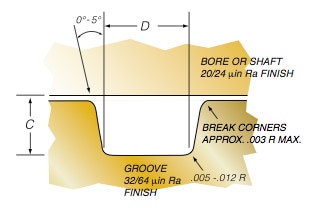

Volume change than static seals C Different design guidelines should be used for groove dimensions for static and dynamic seals QUALITY SEALS 2 GROOVE DIMENSIONS AND MACHINING CONSIDERATIONS Groove Design BRëAK CORNEAS 005 MAX GROOVE WIDTH 90 R Dynamic Squeeze Industrial Static and Dynamic Seal Glands ORing Cross Section 040 050Additional HDS design options ;As shown in Illustration 47, orings may be used as seals for rotating shafts, with the turning shaft protruding through the ID of the oring The most important factors to consider in designing rotary seal glands are application temperature limits, frictional heat buildup, oring stretch, squeeze and shaft and glandular machining

Www Applerubber Com Src Pdf Seal Design Guide Pdf

Oring Ehandbook

To seal the mechanical seal elements to the rotating shaft to prevent leakage along the shaft, two basic types of seals are used (a) pusher type using springs and seal "O" rings, wedge rings, and so on;An Oring is a torus, or doughnutshaped ring, generally molded from an elastomer, although Orings are also made from PTFEThose who are already familiar with Oring seal design may simply refer to the appropriate design tables for the information needed Even those who have designed many Oring seals may profi t by reviewing the basics from time to time 11 What is an ORing?

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

O Ring Calculator Ceetak Sealing Solutions

M Seals specialises in seals for industrial use;Nitrile shaft seals are used as oil seals and are designed to keep your equipment running smoothly They're used in automotive, rail and marine applications as well as in pumps and mining We stock Nitrile seals from major brands such as SKF, and all products are covered by our noquibble moneyback guarantee so that you can order your seals with confidence Viton shaft seals do

O Ring Groove Design Global O Ring And Seal

How To Measure And Identify Oil Seals Polymax Blog

Ring Seal An Overview Sciencedirect Topics

Oil Seal Design Selection Gbsa Inc

Seals And Sealing Technology Hydraulics Pneumatics

Www Hitechseals Com Includes Pdf O Ring Brochure Pdf

Self Centering Seals Design

Groove Design O Ring Seals Minnesota Rubber Plastics

Rotary Seals Design For Construction Machinery Dms Seal Manufacturer

Sealink Sealing Mechanism Lubricant Free Mechanical Seal Design Sealink

1

What Is A Mechanical Seal Aesseal

Buy O Rings Seals Custom Molded Rubber Engineered Plastic All Seals

Seal Design An Overview Sciencedirect Topics

Seal Solutions Guide

O Ring Seals Roy Mech

Metric O Ring Groove Design Reference Guide

O Ring Groove Design Global O Ring And Seal

Radial Shaft Seals Dynamic Rotary Lip Seals Freudenberg Fst

Shaft Seal Ksb

Static O Ring Face Seal Groove Design Guide

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

.jpg)

An Introduction To Ptfe Lip Seals For Rotary Applications

O Ring Groove Design Global O Ring And Seal

O Ring Wikipedia

1

O Ring Groove Design Sealing Australia

O Ring Groove Design Global O Ring And Seal

Dynamic Reciprocating Gland Design Dynamic O Ring Gland

Design Of O Ring Seals Ppt Video Online Download

What You Need To Know About Dynamic Seal Applications Hot Topics

Groove Design O Ring Seals Minnesota Rubber Plastics

Kalsi Seal Introduction High Pressure Shaft Seal Designs

O Ring Groove Design Seal Design Inc

Quad Ring Groove Design Daemar Inc

Quad Rings All Seals

Types Of Seals A Thomas Buying Guide

Protech Bearing Isolator Made By Parker The Hope Group Largest Parker Distributor In New England

O Ring Groove Design Daemar Inc

Inch And Metric Oil Seal Types Gbsa Oil Seal Manufacturers

Shaft Seals For Rotating Shafts

Rotary Shaft Seal Shaft Seals American High Performance Seals

Seal Design O Ring Design O Ring Design Guide

Www Comoso Com Uploads Showcase Manuals Parker Comoso Rotary Seal Design 5350 Pdf

O Rings O Yeah How To Select Design And Install O Ring Seals Youtube

Types Of O Ring Applications

Carbon Graphite Mechanical Seal Types

Shaft Seal Ksb

Buna O Ring O Ring In Houston And Minneapolis Dichtomatik

Cost Effective High Performance O Rings Trelleborg

An Introduction To The Five Key Features Of Good Mechanical Seal Design Reliability Matters

Mating Ring An Overview Sciencedirect Topics

Rotary Sealing Solutions Radial Oil Seals And V Rings Youtube

Single Seals For Caustic Environment In Pumps

What Is An O Ring Selection Material And Storage Barnwell

O Ring Wikipedia

1

Dynamic Rotary Gland Design Dynamic O Ring Gland

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

What You Need To Know About Dynamic Seal Applications Hot Topics

Rotary Shaft Seals Seal Design Inc

What You Need To Know About Dynamic Seal Applications Hot Topics

O Rings And Seals Flat Rubber Seal Ring O Ring Seal High Temperature O Rings Fuel O Rings Freudenberg Fst

Rotary Sealing With High Pressure Seals Kalsi Engineering

O Ring Groove Design Sealing Australia

What Are Rotary Shaft Seals Cinchseal

What Is A Mechanical Seal Aesseal

Fundamental Of O Ring

Vane Shaft And Seal Design The Critical Difference In Pneumatic Rotary Valve Actuators Kinetrol Pneumatic Rotary Vane Actuator Blog

Diagram Of The Face Seal Design 1 Seal Ring Flexibly Attached 2 Seal Download Scientific Diagram

O Ring Groove Design O Ring Groove Dimensions Mykin Inc

Specification For Low Cross Section Seals Skf

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

1

Dynamic O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

Balance In Mechanical Seals Choosing Pumps For Condition Monitoring Pumps Systems

0 件のコメント:

コメントを投稿